“Without CO2 we don’t have a food and beverage industry as we know it. It’s that simple. And without vaporizers, the CO2 the industry needs simply does not work.” This bold statement comes from Jim Hanly, Director of Product Development at vaporizer manufacturer FinnCo, who knows a thing or two about the use of carbon dioxide across myriad industries.

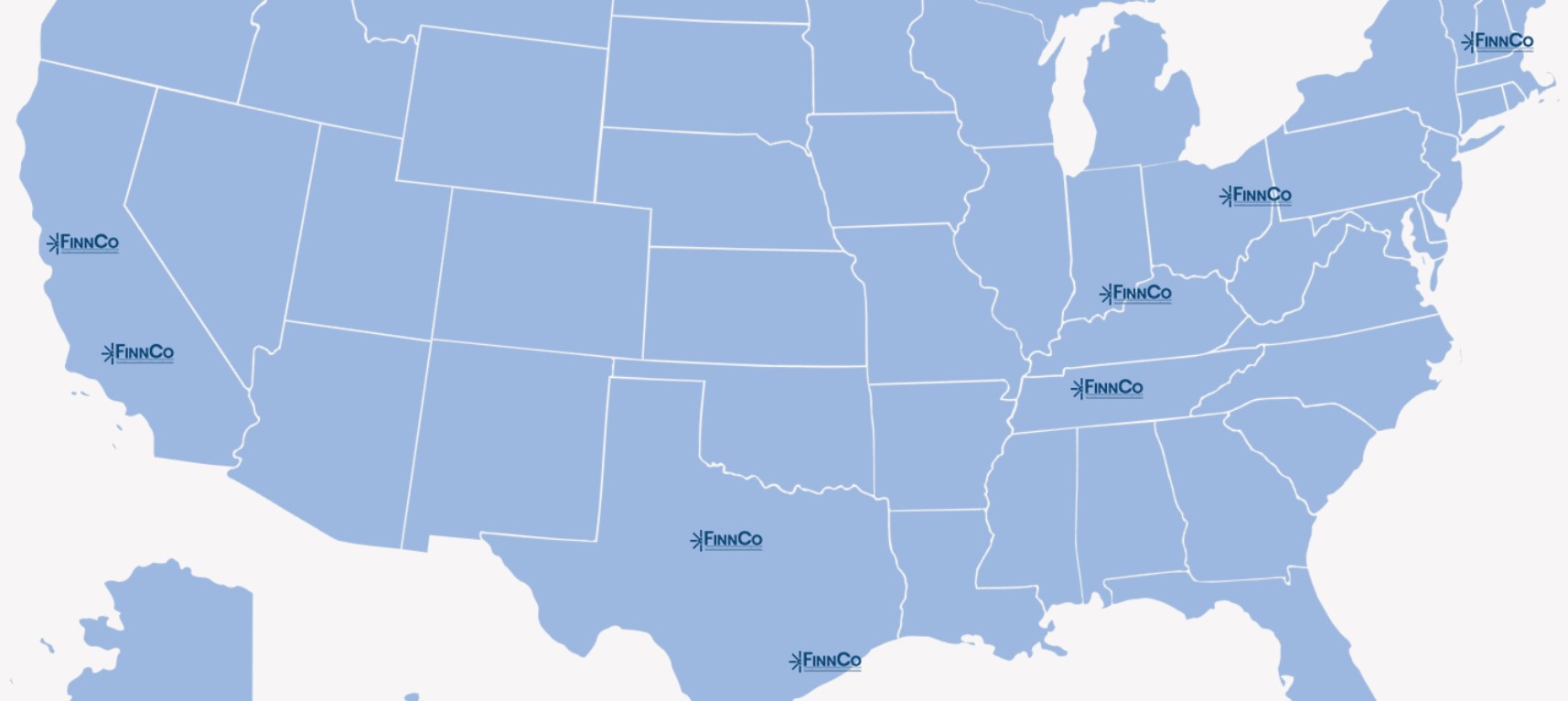

FinnCo is the vaporizer arm of FIBA Technologies, the leading manufacturer of high pressure gas storage and transportation solutions. Turnover at FinnCo almost doubled in 2023 after Hanly and his team broadened its offer to now include CO2 and water-circulating vaporizers alongside its direct steam, electric and ambient products.

This approach has seen FinnCo secure contracts to supply into a wide variety of sectors, including hydrogen, aerospace and medical. Within the food and drink industry the vaporizer is seen as integral to the entire range consumer products.

“Vaporizers really come into their own in the beverage industry,” explains Jim Hanly.

“The carbon dioxide in beverages not only creates the carbonation leading to the characteristic bubbles in soft drinks and sparkling waters, but also acts as a preservative.

“Carbon dioxide can also be used as a tank blanket to keep it pressurized and prevent oxygen and impurities from contaminating beverages, which is true especially for beer brewers. Carbon dioxide is provided to beverage packagers in the form of a liquid which requires vaporization prior to addition to the beverage.”

Case study: Best Bev of Waverly, NY.

Leading beverage manufacturer, Best Bev operates a 130,000 sq. ft. facility in New York state where it delivers a full range of services to the US beverage industry. With everything from tunnel pasteurization and in-line cartoning, to variety packing and even an on-site testing lab, Best Bev produces everything from seltzers and teas to canned cocktails and wines.

Project Manager, Jack Blobe, explains how the company serves its customers: “We’re a contract manufacturer, we produce just about anything that you can put into an aluminium beverage can. We work as a one stop shop, we blend, fill, and package into various paperboard/corrugate containers, both straight flavor and variety packs.

“It’s key that we offer formulation, material sourcing, filling, variety packing, and warehousing services all under one roof.”

Best Bev’s high-speed lines can run any can size, working with both new beverage brands as well as established brands seeking to expand into new markets or increase their production capacity.

Gas plays a major part in their production, with Nitrogen being used for dosing into non-carbonated products and as a process gas in batching.

CO2 is central to the process as well. As Jack Blobe says: “We use CO2 to carbonate with our in-line blenders before the finished liquid is sent to our fillers. It’s the industry standard way of operating and we have used FinnCo’s vaporizers, via FIBA, for some years. We had them installed at our previous, smaller facility over the state border in PA, so when we moved to our new larger facility in NY it made perfect sense to utilize FinnCo’s vaporizers here too.”

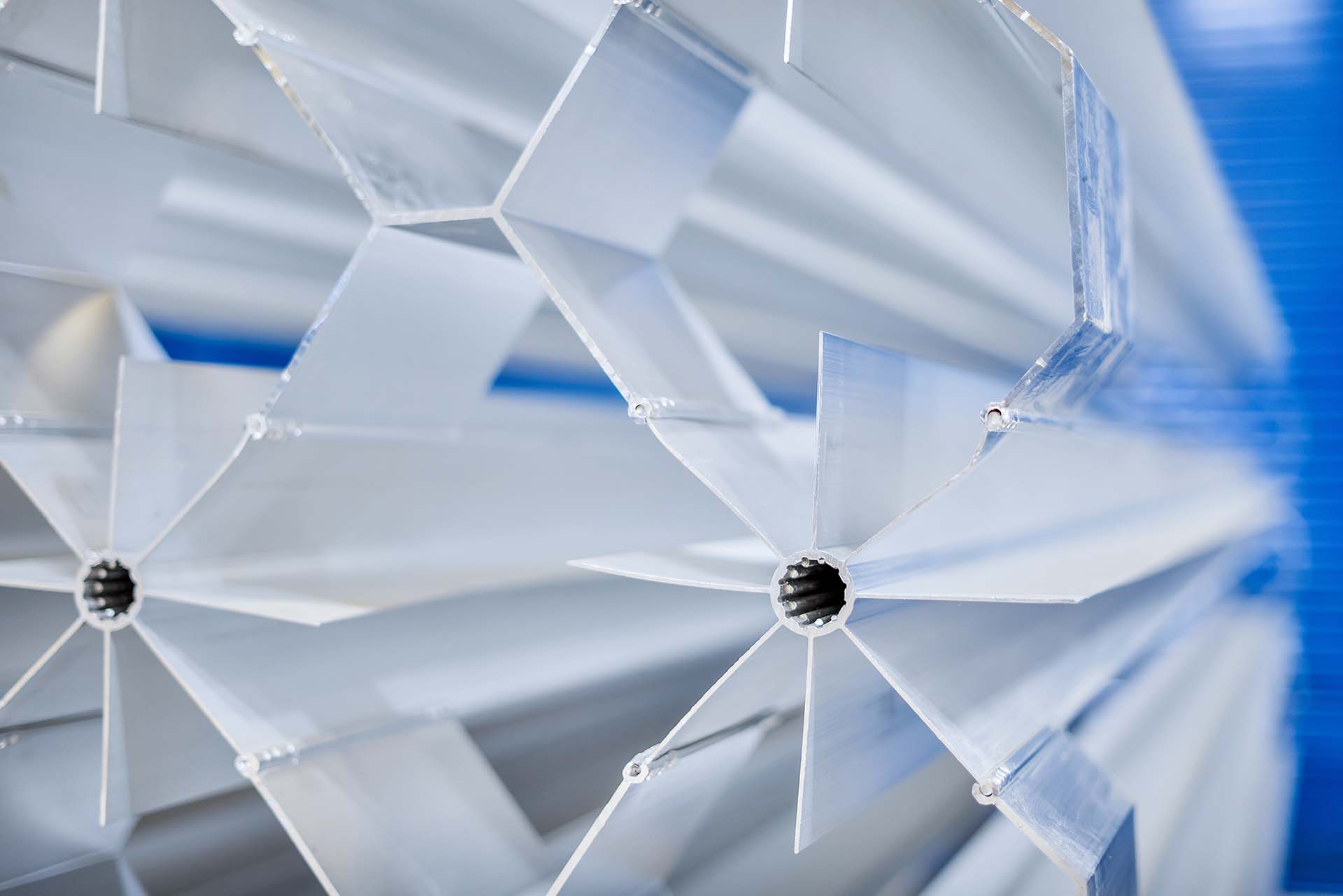

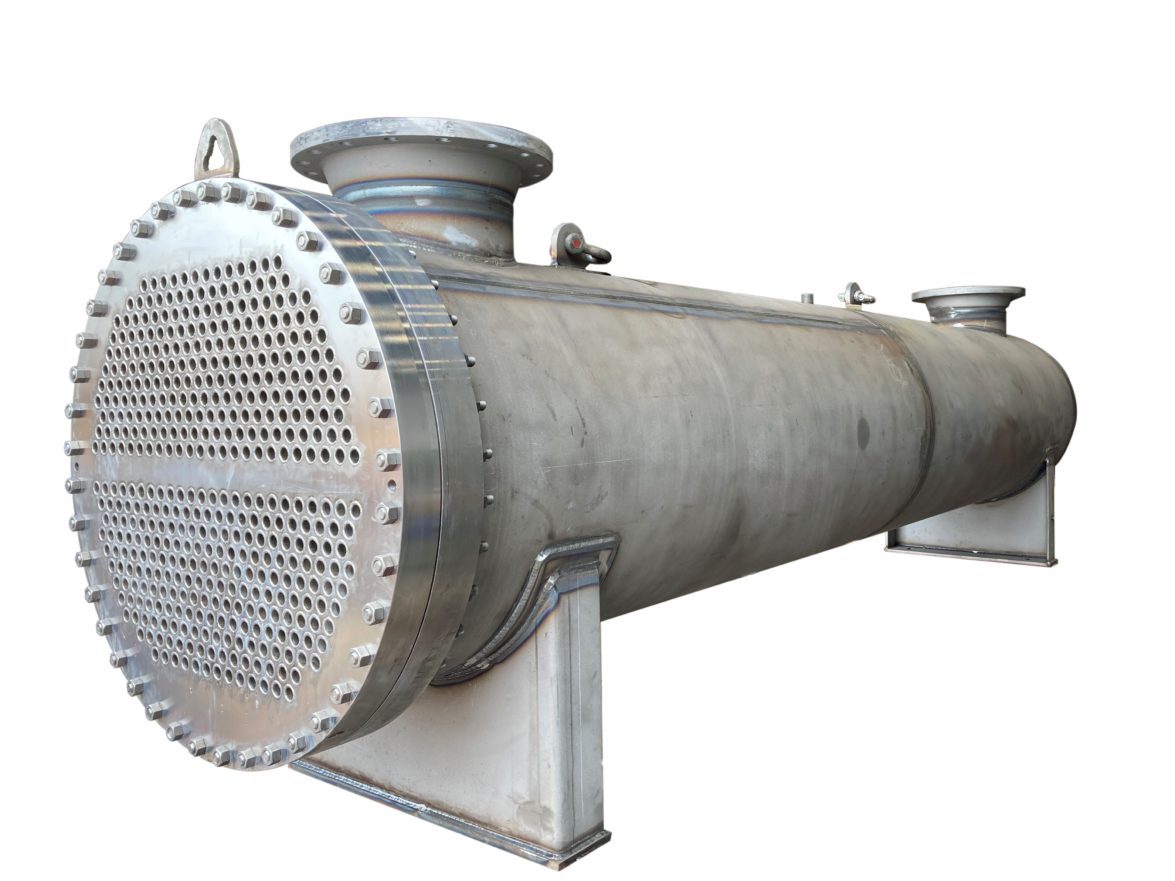

With Best Bev’s location in the Northeast, FinnCo’s FinnStack electric vaporizers were the company’s best solution for vaporizing CO2. The FinnStack vaporizer uses 480Vac/3p power to heat modular aluminum blocks that transfer that heat to the liquid CO2.

CO2 vapor that is temperature-controlled by the vaporizer is injected under pressure into the beverage process line. Some locations in warmer climates can use ambient air vaporizers or a combination of ambient and electric vaporizers to reduce operating costs.