Ambient

Our low-pressure, ambient, cryogenic vaporizer line is designed for a maximum pressure of 700 PSI. Our standard high-pressure line is built with a stainless steel lining and is designed for a maximum allowable pressure of 10,000 PSI. The pressure-building vaporizers are designed for a 700 PSI maximum. Monel lined models are also available.

Standard Features

- Simple Assembly

- No Welding Required

- Expandable, Modular Design

- Stackable with No Crating Required

- Custom Accessories Available

Options

- Low & High-Pressure and Pressure-Building Models

- Fins Designed for Maximum Surface Area

- Wide-Gap Design for Superior Air Flow

- Customized Models Available for Special Applications

| Optional Connection types | Design Pressure | |

|---|---|---|

| MNPT (male pipe threads) | 700 psig | 48 barg |

| 150 lb ANSI F.F. flange | 275 psig | 19 barg |

| 300 lb ANSI F.F. flange | 450 psig | 31 barg |

| Mueller T&G Flange (Solder OD) | 700 psig | 48 barg |

Electric

FinnStack cryogenic electric vaporizers are available as direct to process, gas trim heaters, pressure builders, and combination vaporizer/pressure builders. They are available with two control options—standard on/off and enhanced PLC controlled cascade heating. Aluminum heat transfer plates with cold stretched stainless steel liners are stacked between cast-in heating elements providing excellent heat transfer and a configurable modular design.

Standard Features

- On/off outlet temperature control with Indication

- 24Vdc controls for safety

- NEMA 4 UL cabinet

- Dual High block temperature warning and shut down

- Replaceable heaters

- ASME built to 400 psig

- Forklift portable base

Options

- Triple tier cascade heater control

- Low outlet temperature shut off including indicating controls

- Pressure build control including pressure switch and shut off valve

- MAWP to 3000 psig

- Configurable for custom flowrates and pressure drops

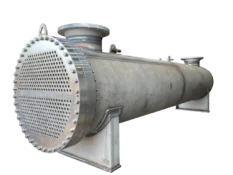

Direct Steam

FinnCo Direct Steam Vaporizers use steam as a heat source to vaporize and superheat cryogenic fluids providing a compact footprint and cost efficient design.

Specifications

- Cryogenic SS tube bundle rated at 250 psig @-320/+350°F; TEMA compliant

- Carbon steel shell rated at 100 psig @-20/+350°F

- Shell and tube bundle to be ASME Sec VIII stamped

- Insulated shell with aluminium jacket

Options

- Customized for various steam pressures and process conditions

- Low outlet temperature shut off

- Spare tube bundles

- Control tie-ins to plant DCS

- Block and bypass around control valve

- Pressure building circuit

| Standard Direct To Process Model | Flowrate: N2, SCFH and CO2, lbs/hr | |

|---|---|---|

| FS-60K-6 | 61,000 | 5,000 |

| FS-120K-8 | 123,000 | 10.000 |

| FS-180K-10 | 184,000 | 15,000 |

| FS-250K-10 | 245,000 | 20,000 |

| FS-300K-12 | 306,000 | 25,000 |

| FS-600K-14 | 613,000 | 50,000 |

| FS-900K-16 | 919,000 | 75,000 |

| FS-1200K-18 | 1,225,000 | 100,000 |

Water-Circulating Vaporizer

FinnCo Water Circulating Cryogenic Vaporizers use existing cooling or heating water circuits to vaporize and superheat cryogenic fluids, providing a low capital cost and low maintenance vaporizing system. The fully customizable Water Circulating Cryogenic Vaporizer can use water as cold as 50°F or glycol/water down to 30°F as a heat source for direct to process vaporization or cryogen disposal.

Manufactured with stainless steel product contact pressure parts to TEMA standards, they have ASME Sec VIII-stamped shells and tube bundles.

SPECIFICATIONS

- Cryogenic SS tube bundle rated at 250 psig @-320/+150°F; TEMA compliant

- Carbon steel shell rated at 75 psig @-20/+150°F

- ANSI flanges

- Lifting lugs

- Vent and drain connections

OPTIONS

- Customized for various process conditions and water flow rates

- Pressure building circuit

- Gas-fired water heater and pump circuit

- Various alloys available

Carbon Dioxide Vaporizer

FinnCo provides Ambient and Electric Vaporizers dedicated to Carbon Dioxide and are available for low pressure and high pressure supercritical applications.

To meet the growing needs of sectors ranging from beverage manufacture to gas distribution, and from food packaging to medical uses, the entire range of direct to process vaporizers and pressure builders is fully-customizable.

SuperFin CO2 Ambient Vaporizers

Specific CO2 Features

- Maximum surface extrusions with 16 fins for high boiling Carbon Dioxide

- Wide gap design for superior air flow and run length

- Standard design to 700 psig

- Low height models available for indoor applications

FinnStack Modular Electric Vaporizers

Specific CO2 FinnStack Features

- Higher allowed block temperatures for higher outlet temperatures

- Greater surface area for higher boiling CO2

- Pressure ratings to 3000 psig

Thermosyphon Electric Pressure Builder

Specific CO2 Model Features

- Built to ASME B31.3, MAWP = 400 psig

- UL immersion heater with incoloy elements and heavy duty NEMA 4 heater head

- Adjustable NEMA 4 pressure switch and level switch

- Electrically actuated shut off ball valve

- Can be tank mounted