Ambient

Standard Features

- Simple Assembly

- No Welding Required

- Expandable, Modular Design

- Stackable with No Crating Required

- Custom Accessories Available

Options

- Low & High-Pressure and Pressure-Building Models

- Fins Designed for Maximum Surface Area

- Wide-Gap Design for Superior Air Flow

- Customized Models Available for Special Applications

| Optional Connection types | Design Pressure | |

|---|---|---|

| MNPT (male pipe threads) | 700 psig | 48 barg |

| 150 lb ANSI F.F. flange | 275 psig | 19 barg |

| 300 lb ANSI F.F. flange | 450 psig | 31 barg |

| Mueller T&G Flange (Solder OD) | 700 psig | 48 barg |

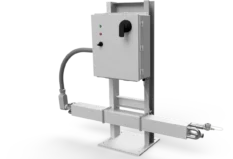

Electric

Standard Features

- On/off outlet temperature control with Indication

- 24Vdc controls for safety

- NEMA 4 UL cabinet

- Dual High block temperature warning and shut down

- Replaceable heaters

- ASME built to 400 psig

- Forklift portable base

Options

- Triple tier cascade heater control

- Low outlet temperature shut off including indicating controls

- Pressure build control including pressure switch and shut off valve

- MAWP to 3000 psig

- Configurable for custom flowrates and pressure drops

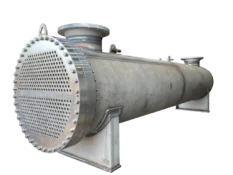

Direct Steam

Specifications

- Cryogenic SS tube bundle rated at 250 psig @-320/+350°F; TEMA compliant

- Carbon steel shell rated at 100 psig @-20/+350°F

- Shell and tube bundle to be ASME Sec VIII stamped

- Insulated shell with aluminium jacket

Options

- Customized for various steam pressures and process conditions

- Low outlet temperature shut off

- Spare tube bundles

- Control tie-ins to plant DCS

- Block and bypass around control valve

- Pressure building circuit

| Standard Direct To Process Model | Flowrate: N2, SCFH and CO2, lbs/hr | |

|---|---|---|

| FS-60K-6 | 61,000 | 5,000 |

| FS-120K-8 | 123,000 | 10.000 |

| FS-180K-10 | 184,000 | 15,000 |

| FS-250K-10 | 245,000 | 20,000 |

| FS-300K-12 | 306,000 | 25,000 |

| FS-600K-14 | 613,000 | 50,000 |

| FS-900K-16 | 919,000 | 75,000 |

| FS-1200K-18 | 1,225,000 | 100,000 |

Water-Circulating Vaporizer

SPECIFICATIONS

- Cryogenic SS tube bundle rated at 250 psig @-320/+150°F; TEMA compliant

- Carbon steel shell rated at 75 psig @-20/+150°F

- ANSI flanges

- Lifting lugs

- Vent and drain connections

OPTIONS

- Customized for various process conditions and water flow rates

- Pressure building circuit

- Gas-fired water heater and pump circuit

- Various alloys available

Carbon Dioxide Vaporizer

SuperFin CO2 Ambient Vaporizers

Specific CO2 Features

- Maximum surface extrusions with 16 fins for high boiling Carbon Dioxide

- Wide gap design for superior air flow and run length

- Standard design to 700 psig

- Low height models available for indoor applications

FinnStack Modular Electric Vaporizers

Specific CO2 FinnStack Features

- Higher allowed block temperatures for higher outlet temperatures

- Greater surface area for higher boiling CO2

- Pressure ratings to 3000 psig

Thermosyphon Electric Pressure Builder

Specific CO2 Model Features

- Built to ASME B31.3, MAWP = 400 psig

- UL immersion heater with incoloy elements and heavy duty NEMA 4 heater head

- Adjustable NEMA 4 pressure switch and level switch

- Electrically actuated shut off ball valve

- Can be tank mounted

Lower Power Applications

Specifications

- On/Off temperature control

- High block temperature warning/Shut down with manual reset

- Replaceable heaters

- ASME built to 400 PSIG

- NEMA 4 UL cabinet

Options

- Pressure build control including pressure switch and shut off valve

- MAWP to 3000 psig

Electric Water Bath Vaporizers

Specifications

- Cryogenic SS tube bundle rated at 250 psig (400 psig for C02) @ -320/+150°F; TEMA compliant, ASME Sec VIII stamped

- Carbon steel shell rated at 15 psig @ -20/+220°F; built to ASME Sec VIII

- NEMA 4 cabinet

- Replaceable Heaters

Options

- Customized for various process conditions including high pressures

- Vertical high pressures

- Multiple bundles including pressure building circuit

- Insulated tank with aluminum jacket.